Most motorists know firsthand the negative effects of low temperatures on the battery. At temperatures below 15 degrees Celsius, a loss of capacity by 1 Ah occurs. Each subsequent negative degree will reduce the capacity by another 1 Ah. Therefore, in severe frosts, the ability to start the engine is reduced.

At the same time, oil thickens in the gearbox and engine, the candles are covered with ice, etc. So you need a higher power to start. The thermal case is designed to solve these battery problems.

The use of a heated case with battery helps:

- Confident start of the vehicle even at a temperature below - 40 degrees C.

- Saving money, personal time motorist.

- Extend the battery life without additional maintenance.

Content

What is and why is a thermal case needed

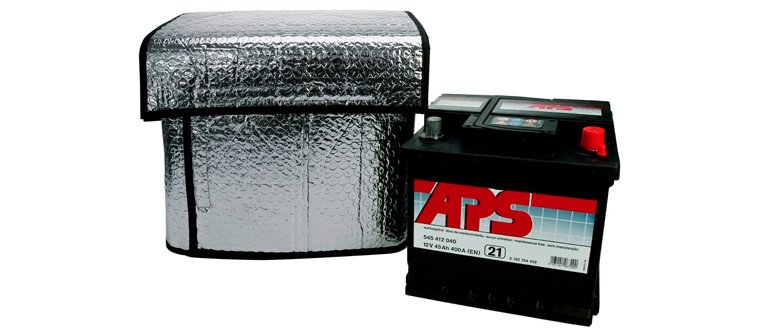

The product protects the battery from overheating, freezing. The thermal box device allows you to save heat for a long period, due to this, a quick engine start is provided. Another function is to prevent battery overheating in the summer. During this period, the temperature under the hood cover rises to 90-100 degrees Celsius.

Thermal case solves important problems:

- Prevents thermal shock on batteries;

- helps to heat the battery during engine operation for further full charge before parking for many hours;

- helps to slow down the cooling of the battery in the cold during prolonged parking;

- gives a warning when starting the engine about low charge and improper charge when the engine is running;

- protects the device from mechanical damage, moisture and dirt.

This is due to the design features of the thermal case. It consists of a housing (thermos) and NTA (heater with a car temperature controller). These two devices are independent of each other.

Types of thermal cases for the battery

For the uninterrupted operation of the battery at different temperature indicators, two types are offered:

- Thermal case without heating. Thermos has a multilayer design without a seam. Bottom - with insert. Made from modern materials.

- Thermal case with heating. Low voltage plates are built into it. They create heat inside the device, which is held by the principle of a thermos in a thermal case.

Plates made of PCB or plastic consume 20-40 watts of energy and are located on wide sides of the power source, which becomes warm and perfectly accepts charge. You can easily change the parameters of the heating element. The dimensions of the plate, as well as the power, without problems increase from 30% to 100%. This does not affect the electrical network of the machine.

How to choose

To protect the unit from minus indicators, the car power supply is "packed" in a thermal case. To make the right choice, you must adhere to the basic rules:

- in the place of attachment of the battery should be a margin of 1-1.5 cm on each side;

- take measurements of the battery in height, width, length. Take into account the height of the battery with the terminals. View information on the Internet;

- find out what type of housing the battery has (American, Euro, Asia);

- consider the difference in diameter and arrangement of the terminals;

- when choosing NTA, consider the length of the plates. It should not be longer than the battery;

- the product must match the dimensions of the battery, the method of attachment.

Please note: Due to the use of materials resistant to the negative effects of moisture, acid, high temperatures, the operating life of thermal cases is unlimited.

How to use a battery thermal case

Before using the thermal box, it is necessary to place the battery in it correctly. For this:

- A heat shield is inserted at the bottom of the thermal cover.

- The battery is placed in a thermal case and installed in the hood of the car.

- The terminals are connected and the thermos cover is closed so that there are no gaps.

- The position of the battery is fixed using fasteners.

NTA (electronic device) must be turned on with the engine running. Additional control over it is not required. Heating of the element begins only when the temperature in the thermos decreases to +5 - 0 C. After reaching the thermos temperature of + 25 ° C, and also when the motor is stopped, the heating of the NTA stops. For the summer period, the heater is not dismantled.

DIY battery case

The main enemies of the battery are heat, frost, low / high charge, mechanical damage, dust, self-loading. Avoiding many problems will help self-manufacturing thermal box. Many motorists use penophenol for this. The main heat-insulating element is a foamed polyethylene having a reflective surface.

To independently make a thermal bag, you need to prepare the following materials and tools:

- Foamed penophenol - 1 sq.m.

- Ruler, felt-tip pen.

- Velcro, adhesive tape, thread, needle.

It is necessary to measure the dimensions of the battery. To do this, it is dismantled and dimensions are determined by height, width, length. To make the cutting of the insulation, you can transfer the dimensions to the paper, and then make a pattern. Be sure to consider seam allowances - 1.5-2 cm.

Attach the resulting template to penophenol, mark with a felt-tip pen and cut along the contour. Then glue with adhesive tape or stitch the product along the edge.

Attach Velcro to the cover.

Many motorists insulate the power source by wrapping it with penophenol. However, one layer of insulation is not enough to create the effect of a thermos. Therefore, first the battery is wrapped with insulation so that the shiny surface is inward.

Next - the outer layer is formed - the foil surface out. This will delay the rapid release of heat from the source to the outside.

The shiny part outside will repel heat. In the same way, they act not only with the side, but also the upper, lower parts of the power source. Penophenol is well bonded with construction tape.

This is the simplest case. As a heater, foam can be used. However, such characteristics of penophenol as flexibility, resistance to moisture, good thermal insulation make it the most suitable for creating a thermos. In addition, it is possible to make a cover made of an acid-resistant fabric and to put on the thermal product.

Still have questions aboutThermal case or have something to add? Then write to us about it in the comments, this will make the material more useful, complete and accurate.

Reviews

- The first winter, my Lada quietly spent in the parking lot. A thermal case nevertheless turned out to be very useful. I did not have to remove the battery, as usual, so as not to freeze.

- In winter I was satisfied. Actually, the battery remained at a positive temperature even with a frost of -20. I haven’t checked yet in the summer. Still to come.

- Simple and well thought out. Now I don’t have to ask my neighbor to pull in the morning every time. The first hot days also showed that the thermal case works fine, holding up the hot outside air.